The hop plant is host to the hop-dog caterpillar and we are very happy to report that there has been an increase in sightings of these caterpillars this year. It is lovely to see them increasing in numbers..…I wonder was it the weather conditions this summer or just luck in spotting them? But as I am working in the hops one downside of this is that I have not been able to take the time out to photograph these caterpillars as I would have liked to, one would always turn up at the most inconvenient moment!

The hop plant is host to the hop-dog caterpillar and we are very happy to report that there has been an increase in sightings of these caterpillars this year. It is lovely to see them increasing in numbers..…I wonder was it the weather conditions this summer or just luck in spotting them? But as I am working in the hops one downside of this is that I have not been able to take the time out to photograph these caterpillars as I would have liked to, one would always turn up at the most inconvenient moment!

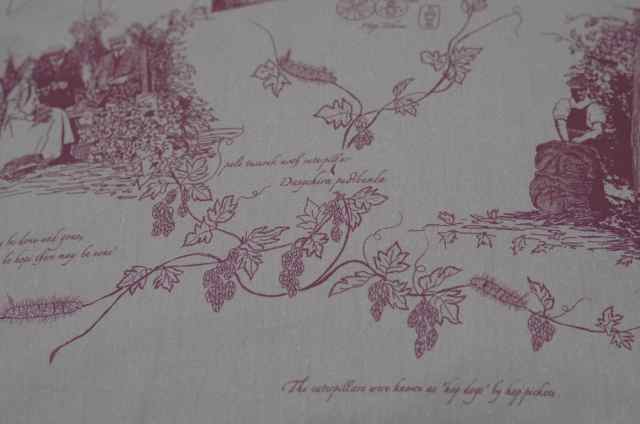

The hop-dog caterpillar holds fond memories for hop-pickers from the hand-picking days. Children enjoyed finding them with their yellow furry bodies and distinctive red tails. Warnings that they would give you a nasty rash if picked up, probably saved many a little creature from well intentioned over-handling! I have of course included them on the Hop Toile fabric as they deserve their place in the ‘hop story’.

The little fellow shown here below had amazingly been right through the hop-picking machine, before being shelved from a full poke and miraculously landing safe and sound on top of the bed of hops in the kiln of the oast house. Luckily he was spotted and rescued before drying of that particular load began. If he’d been cat he would have used up all his nine lives in this one adventure!

We like to see them and don’t consider them pests, we certainly haven’t noticed any damage done by them. After all a mature lush hop garden is a pretty copious and abundant environment with plenty of leaves to go around.

For some extra images and information about the hop-dog caterpillar see this blog post by Doug Mackenzie Dodds. He has taken the photos I wished I had taken, and not even in a hop garden!

I would like to spot the grown-up version of the hop-dog now, the excellently camouflaged Pale Tussock moth. Earlier this year I did see two equally well camouflaged moths, a pair of poplar hawk moths mating on our car wheel. Their camouflage proved pretty hopeless against the black background, which actually made them stand out.

This has not been a ‘normal’ growing year. However, the long

This has not been a ‘normal’ growing year. However, the long

All photographs for this post were taken by Dave Berry and used with his kind permission.

All photographs for this post were taken by Dave Berry and used with his kind permission.

magical silver linings within those cloudy skies.

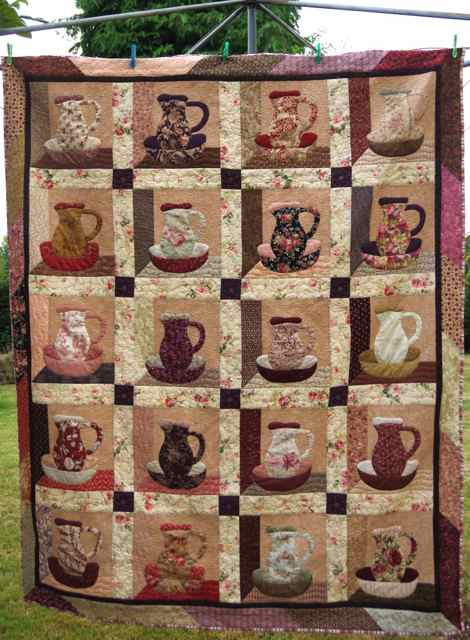

magical silver linings within those cloudy skies. I really wanted to use the latest Hop Fabric designs in cotton poplin supplied by

I really wanted to use the latest Hop Fabric designs in cotton poplin supplied by

The result is I have already missed having this easy appliqué project but have an idea for another one. This time round the blocks will be smaller and just as before easily carried in a small bag. It is surprising how much you can get done by only sewing for the odd few minutes now and then. At least waiting isn’t boring anymore.

The result is I have already missed having this easy appliqué project but have an idea for another one. This time round the blocks will be smaller and just as before easily carried in a small bag. It is surprising how much you can get done by only sewing for the odd few minutes now and then. At least waiting isn’t boring anymore.

Alongside today’s larger sleeker combines she may look like a joke with her 7 foot cutting head, but she is feisty, although undeniably grubby and tricky to handle. No matter, the all important resulting end grain sample is equal if not better than many of the samples from these more modern sophisticated combines. The 187 does her job well.

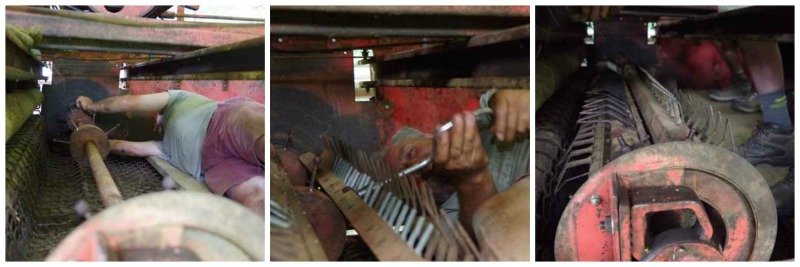

Alongside today’s larger sleeker combines she may look like a joke with her 7 foot cutting head, but she is feisty, although undeniably grubby and tricky to handle. No matter, the all important resulting end grain sample is equal if not better than many of the samples from these more modern sophisticated combines. The 187 does her job well. Over the last ten years little has had to be done, other that general servicing, but this year the two jobs we knew should have been dealt with, did not get done. This was because of work needed on the

Over the last ten years little has had to be done, other that general servicing, but this year the two jobs we knew should have been dealt with, did not get done. This was because of work needed on the  First was the main drum-drive belt. We were very grateful that our clever local combine engineer was able to replace this promptly with out much ado. However, with rain imminent the second breakdown needed a speedy running repair. Full credit has to go to my husband Richard for this very practically inspired repair and to the combine for being basically engineered. This could not have been so simply achieved on one of the large computer programmed combines, so she won the day and completed the harvest for another year.

First was the main drum-drive belt. We were very grateful that our clever local combine engineer was able to replace this promptly with out much ado. However, with rain imminent the second breakdown needed a speedy running repair. Full credit has to go to my husband Richard for this very practically inspired repair and to the combine for being basically engineered. This could not have been so simply achieved on one of the large computer programmed combines, so she won the day and completed the harvest for another year.

Today it has rained putting pay to harvesting for the time being.

Today it has rained putting pay to harvesting for the time being.

Their present large numbers are a scourge for growers and woodland alike. Fruit trees are damaged as the deer go after the ripening fruit. Groups of deer roam freely between different farms at will, thereby making a mockery of Stock Movement Records on local farms.

Their present large numbers are a scourge for growers and woodland alike. Fruit trees are damaged as the deer go after the ripening fruit. Groups of deer roam freely between different farms at will, thereby making a mockery of Stock Movement Records on local farms.

After passing through these first pairs of picking rotors where the bines are stripped of everything, you are left with a mix of some single hops but mostly a mass of laterals and small bunches. Single hops will drop through the chain belt onto a canvas conveyor belt below, whilst the laterals (branches) and bunches all still need be picked. These are conveyed on a chain link belt along to the lateral picker.

After passing through these first pairs of picking rotors where the bines are stripped of everything, you are left with a mix of some single hops but mostly a mass of laterals and small bunches. Single hops will drop through the chain belt onto a canvas conveyor belt below, whilst the laterals (branches) and bunches all still need be picked. These are conveyed on a chain link belt along to the lateral picker. The lateral picker like the main picker section is also horizontal, and this lateral picker lies behind the first main rotary pickers. This lateral picker comprises of a static frame with a set of 4 fixed bars of picking fingers, above a rotor with 8 bars of picking fingers, the lateral is fed through between the static and rotary bars.

The lateral picker like the main picker section is also horizontal, and this lateral picker lies behind the first main rotary pickers. This lateral picker comprises of a static frame with a set of 4 fixed bars of picking fingers, above a rotor with 8 bars of picking fingers, the lateral is fed through between the static and rotary bars.

steel wire and as they do the grunt of the work, they can take a pounding especially with mature hops, hence this year they needed a general service, cleaned of pollen build up and any missing fingers replaced. The static top frame slides out easily enough on rails but to get the rotor out of the machine was easier said than done! As always with older hop picking machines a few modifications have been made – one shown right – this time to make it easier to remove these bars individually in the future, rather than taking out the whole rotor assembly. Now it is done it all looks really good and we can’t wait to see how it picks the hops. Below the renovated lateral picking bars ready for reassemby

steel wire and as they do the grunt of the work, they can take a pounding especially with mature hops, hence this year they needed a general service, cleaned of pollen build up and any missing fingers replaced. The static top frame slides out easily enough on rails but to get the rotor out of the machine was easier said than done! As always with older hop picking machines a few modifications have been made – one shown right – this time to make it easier to remove these bars individually in the future, rather than taking out the whole rotor assembly. Now it is done it all looks really good and we can’t wait to see how it picks the hops. Below the renovated lateral picking bars ready for reassemby