The last major job this year on the Allaeys hop harvester was cleaning the lateral picking fingers and replacing any that were missing. It was one of those ‘just jobs’ which ended up taking days to complete.

Any hop harvester has two basic functions, to pick and then clean the crop. At the front of this Allaeys hop picking machine are sets of horizontal rotors which strip the whole hop bines as they are pulled between them via a track. The Allaeys hop machine is unusual with this horizontal system, most hop picking machines have vertical rotors to pick. Below looking into the mouth of the machine.

After passing through these first pairs of picking rotors where the bines are stripped of everything, you are left with a mix of some single hops but mostly a mass of laterals and small bunches. Single hops will drop through the chain belt onto a canvas conveyor belt below, whilst the laterals (branches) and bunches all still need be picked. These are conveyed on a chain link belt along to the lateral picker.

After passing through these first pairs of picking rotors where the bines are stripped of everything, you are left with a mix of some single hops but mostly a mass of laterals and small bunches. Single hops will drop through the chain belt onto a canvas conveyor belt below, whilst the laterals (branches) and bunches all still need be picked. These are conveyed on a chain link belt along to the lateral picker.

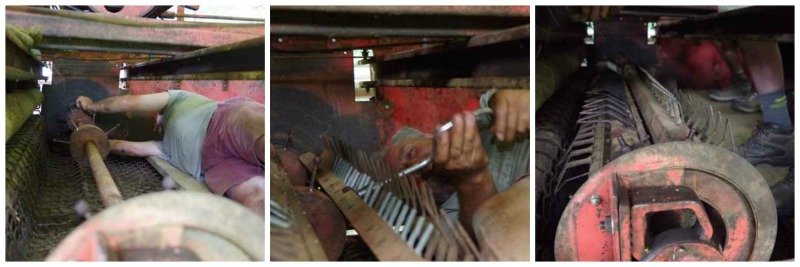

Below inside the beating heart of the Allaeys hop machine, not an easy workspace is an understatement. The lateral picker like the main picker section is also horizontal, and this lateral picker lies behind the first main rotary pickers. This lateral picker comprises of a static frame with a set of 4 fixed bars of picking fingers, above a rotor with 8 bars of picking fingers, the lateral is fed through between the static and rotary bars.

The lateral picker like the main picker section is also horizontal, and this lateral picker lies behind the first main rotary pickers. This lateral picker comprises of a static frame with a set of 4 fixed bars of picking fingers, above a rotor with 8 bars of picking fingers, the lateral is fed through between the static and rotary bars.

Below are the fingers and bars before renovation.

Below from top left clockwise are 1 – spare fingers, 2 – the static frame all ready to go back inside the hop harvester, 3 – the static frame being slid back into the main hop picking machine on its rails and 4 – a close up of the replaced fingers to show how they are joined by springs and fixed with a metal bar bolted to the wooden bar. These wooden bars are then bolted to the metal rotor.

These actual picking fingers or ‘midnight’ fingers (I have no idea why they are known by this name) are made of  steel wire and as they do the grunt of the work, they can take a pounding especially with mature hops, hence this year they needed a general service, cleaned of pollen build up and any missing fingers replaced. The static top frame slides out easily enough on rails but to get the rotor out of the machine was easier said than done! As always with older hop picking machines a few modifications have been made – one shown right – this time to make it easier to remove these bars individually in the future, rather than taking out the whole rotor assembly. Now it is done it all looks really good and we can’t wait to see how it picks the hops. Below the renovated lateral picking bars ready for reassemby

steel wire and as they do the grunt of the work, they can take a pounding especially with mature hops, hence this year they needed a general service, cleaned of pollen build up and any missing fingers replaced. The static top frame slides out easily enough on rails but to get the rotor out of the machine was easier said than done! As always with older hop picking machines a few modifications have been made – one shown right – this time to make it easier to remove these bars individually in the future, rather than taking out the whole rotor assembly. Now it is done it all looks really good and we can’t wait to see how it picks the hops. Below the renovated lateral picking bars ready for reassemby

For anyone interested after the picking, the cleaning is done in two sections by a combination of fans and belts, hopefully at the end you will have a beautiful clean sample of single hop cones. Essentially large fans blow out the leaf and pimply rubber belts do the final cleaning. The basic principal of the belts is that they run at approximately 45 degree angle, the whole hop cones roll down onto a conveyor and the strig and any remaining bits of leaf stick onto the pimply rubber thereby being moved out of the machine as waste. By the end you have two conveyors one with the clean hops ready to be dried and the other with the unwanted plant waste. The coir string used for the hops to climb up is also a plant product, therefore it will naturally biodegrade along with the hop plant waste.

It is tempting fate of course, but this is definitely the last ‘planned’ servicing job for this year! But should we ever feel complacent, I always imagine Willie Wonka around a corner ready to go ‘Surprise’ and throwing a new challenge into the ring !!

I saw this portable hop machine on the internet, it uses rubber picking fingers instead of the usual metal wire ‘V’ ones. It would be really interesting to see it in real life.

This British Pathe film from 1950 shows a hop harvester working.